Umberto Case Studies on the Carbon Footprint and LCA

Umberto can be used to determine either the climate impact (Carbon Footprint) or the overall environmental impacts (LCA) of a product in a wide variety of industrial areas. Read our case studies and learn how companies successfully mastered these challenges.

Carbon Footprint for a Water Filtration System

The manufacturer of the water filtration system BRITA analyzed the Carbon Footprint for an exemplary countertop water filtration system. The analysis shows that - compared to corresponding industry data on bottled water - the water filtration system has a distinctly smaller Carbon footprint.

Carbon Footprint in the Wood Construction

For the family business Janssen Holzbau sustainability is not a state, but rather a continuous improvement process. That’s why the business already implemented resource saving measures. Goal of the Carbon Footprint is to evaluate these measures and prove evidence of their success.

Comparative Life Cycle Assessment of PVC production

VinyLoop® is a relatively young plastic recycling process for PVC. In an LCA study the production based on the Viny-Loop® process was compared to the production of new PVC compounds.

The results show that the VinyLoop® process requires 46% less primary energy and the greenhouse gas emissions can be reduced by 39%.

Carbon Footprint in the

Construction

HOBAS Engineering is a leading manufacturer of high quality pipe systems. In a project for a wastewater system the business systematically evaluated the climate impacts for the first time. For the realization of the project HOBAS examined the CO2 emissions connected to the two different methods of laying the new pipeline.

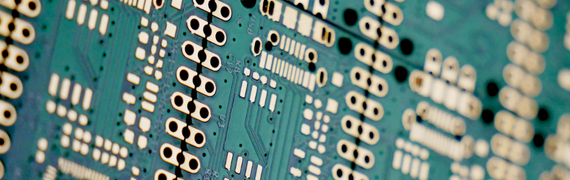

Life Cycle Assessment for Fujitsu Computer Hardware

Together with the bifa environmental institute Fujitsu carried out a Life Cycle Assessment study for computer hardware. The software Umberto was used for the project and showed that the greenhouse gas emissions are the most relevant indicator for the environmental performance and that the use phase has the lion’s share of the total carbon footprint with 50%.

Life Cycle Assessment of

Pipe Systems

HOBAS Engineering a leading manufacturer for pipe systems asked themselves which alternative for unsaturated polyester resins would be more environmentally friendly, the usage of standard-, recycled PET or bio-sourced material. The software Umberto supported them to find an answer to this question.